Workflow for wooden contact samples in use-wear experiments with bronze axe replicas (MAP-protocol_B)

Ulrich Thaler, Walter Gneisinger

archaeology

use-wear

traceology

bronze axes

socketed axes

contact materials

contact samples

experiment

experimental archaeology

bronze age

beechwood

controlled experiment

Abstract

Focussing on the role of contact materials as an element of variable control in archaeological use-wear experiments, this protocol sets out a workflow for the preparation, use and documentation of standardized beechwood contact samples. Although developed in the context of rig-based experimentation with bronze axe replicas as part of MAP , it follows principles and sets out procedures of broader applicability within traceological experimental research in general and in studies involving ligneous contact material in particular. MAP (the M ainz, M ayen & M onrepos A xperimental P rogramme) expands into a 'post-lithic' material class (copper-based artefacts) and chronological setting (the Bronze Age) the research agenda developed by TraCEr, which is based on a strong commitment to open science and an understanding of sustained methodological development as a key to consolidating traceology as a sub-discipline within archaeology.TraCEr (the Laboratory for Tra ceology and C ontrolled E xperiments) was established by the RGZM, the Leibniz Research Institute for Archaeology, at the MONREPOS Research Centre and Museum at Neuwied in 2017. Its main scope is to carry out ground-breaking research that combines methodological development, aided by state-of-the-art facilities for controlled experimentation and advanced methods of documentation, and fundamental research on Pleistocene and Early Holocene archaeology.

Attachments

Steps

Acquisition of contact material

Acquisition of contact material

obtain plank of high-quality beechwood ( Fagus sylvatica ) in a thickness that corresponds to the intended width of your contact samples

48.5 mm thickness (of pre-planed plank, will correspond to contact sample's width)

Preparation of contact samples

Preparation of contact samples

Cutting of blanks

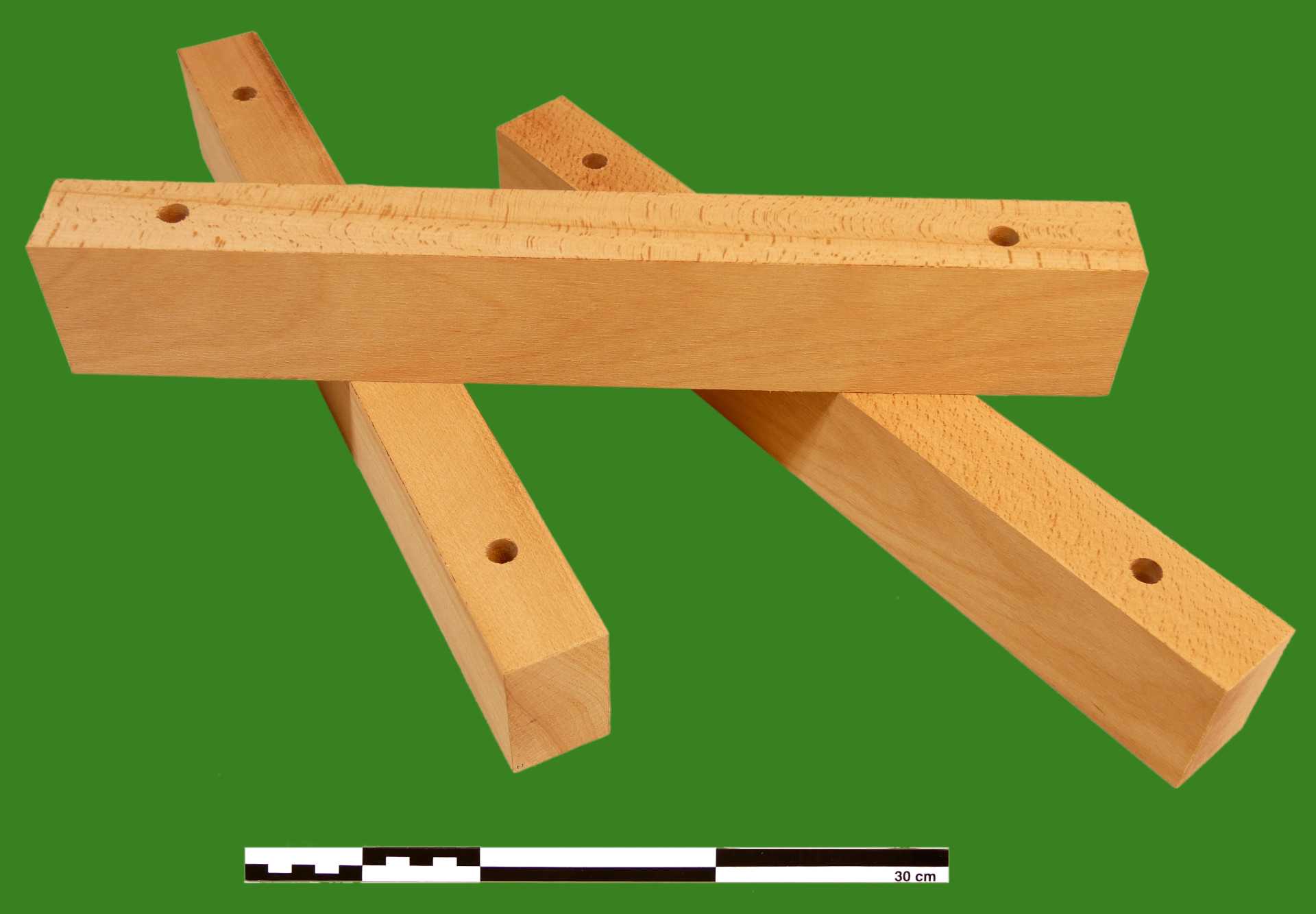

cut blanks of the intended size (length and height) of your contact samples from the plank or have them cut

500 mm length (blank oriented lengthwise in plank)

80 mm height (of finished blanks, corresponds to width while cutting from plank)

Adaptation to contact sample holder

drill holes through contact samples for mounting on contact sample holder, placing them centrally on longitudinal axis on the top (i.e. the narrowest side)

60 mm distance (of centre of drill-holes from ends of contact sample)

14 mm diameter (of drill-holes / drill-bit)

80 mm depth (of drill-holes, equals height of contact sample)

Equipment

| Value | Label |

|---|---|

| TB16 | NAME |

| pillar drill | TYPE |

| Rotwerk | BRAND |

| - | SKU |

| - | LINK |

Conditioning of contact samples

Conditioning of contact samples

bring contact samples to moisture content above fibre saturation point in order to approximate green wood in a controlled manner

Equipment

| Value | Label |

|---|---|

| VTR 5050 K | NAME |

| vacuum oven | TYPE |

| Heraeus | BRAND |

| - | SKU |

| - | LINK |

| run with Atlas Copco GVS 16 A (rotary vane pump) | SPECIFICATIONS |

Equipment

| Value | Label |

|---|---|

| GVS 16 A | NAME |

| rotary vane pump | TYPE |

| Atlas Copco | BRAND |

| - | SKU |

| - | LINK |

Priming vacuum pump

after ensuring that the gas ballast valve of the vacuum pump is open and the valve connecting the pump to the vacuum chamber is closed, start the vacuum pump and leave to idle for 20 minutes

0h 20m 0s

Weighing contact samples

(can run parallel to 3.1)

weigh contact samples (triple measurement); record result(s) along with the date

Equipment

| Value | Label |

|---|---|

| PCB 3500-2 | NAME |

| precision balance | TYPE |

| Kern | BRAND |

| - | SKU |

| - | LINK |

Loading vacuum chamber

(can run parallel to 3.1)

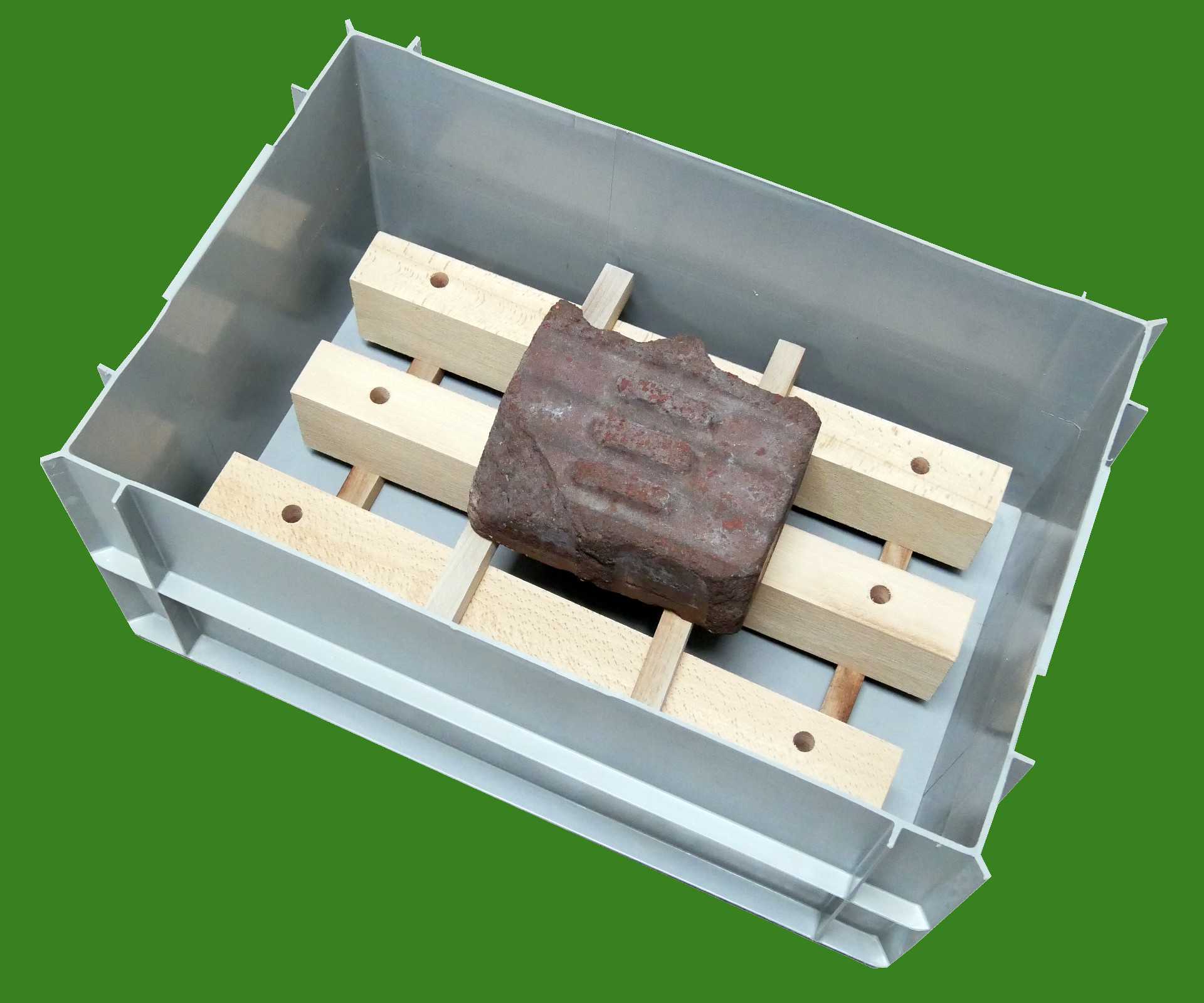

stack contact samples in soaking vat in open-pile fashion with stickers, placing weight on top to counteract boyancy, fill vat with (tap) water up to level of weight and place vat in vacuum chamber

Closing vacuum chamber

(can run parallel to 3.1)

once loaded, close vacuum chamber, taking care to only lightly fasten the clamping levers of the door ('finger-tight') and ensuring that the ventilation valve on the door is closed

Evacuating chamber

by slowly opening the chamber evacuation valve connecting the pump and vacuum chamber, evacuate the chamber; observe pressure gauge and leave valve open for 1 hour after the reading has stopped falling

1h 0m 0s

Safeguarding against condensation in pump

slowly close the chamber evacuation valve and leave vacuum pump to run on idle for 15 minutes, turning it off only after that time has elapsed

0h 15m 0s

Sorption and absorption

leave the contact samples in the evacuated chamber overnight

Opening vacuum chamber

open the ventilation valve on the vacuum chamber door, checking that the door clamping levers do not tighten too much while waiting for normal atmospheric pressure to be re-established inside the chamber; once normal pressure is reached, open door

Weighing contact samples

weigh contact samples (triple measurement); record result(s) along with the date; compare weight to 'target weight'

Equipment

| Value | Label |

|---|---|

| PCB 3500-2 | NAME |

| precision balance | TYPE |

| Kern | BRAND |

| - | SKU |

| - | LINK |

Use-wear experimentation

Use-wear experiment

Weighing contact samples and measuring moisture content

weigh contact samples (triple measurement) immediately before experimental use (for the contact sample used first after the opening of the vacuum chamber, a new measurement may not be needed); measure moisture content with hand-held moisture meter (triple measurement in different spots); record results along with the date

Equipment

| Value | Label |

|---|---|

| PCB 3500-2 | NAME |

| precision balance | TYPE |

| Kern | BRAND |

| - | SKU |

| - | LINK |

Equipment

| Value | Label |

|---|---|

| Moisture Detector MD | NAME |

| hand-held electric moisture meter (conductance meter) | TYPE |

| Brennenstuhl | BRAND |

| - | SKU |

| - | LINK |

Use of sample on contact sample

record sample used on contact sample

Weighing contact samples and measuring moisture content

weigh contact samples (triple measurement) immediately after experimental use; measure moisture content with hand-held moisture meter (triple measurement in different spots); record results

Equipment

| Value | Label |

|---|---|

| PCB 3500-2 | NAME |

| precision balance | TYPE |

| Kern | BRAND |

| - | SKU |

| - | LINK |

Equipment

| Value | Label |

|---|---|

| Moisture Detector MD | NAME |

| hand-held electric moisture meter (conductance meter) | TYPE |

| Brennenstuhl | BRAND |

| - | SKU |

| - | LINK |

Photographic documentation

Photographic documentation

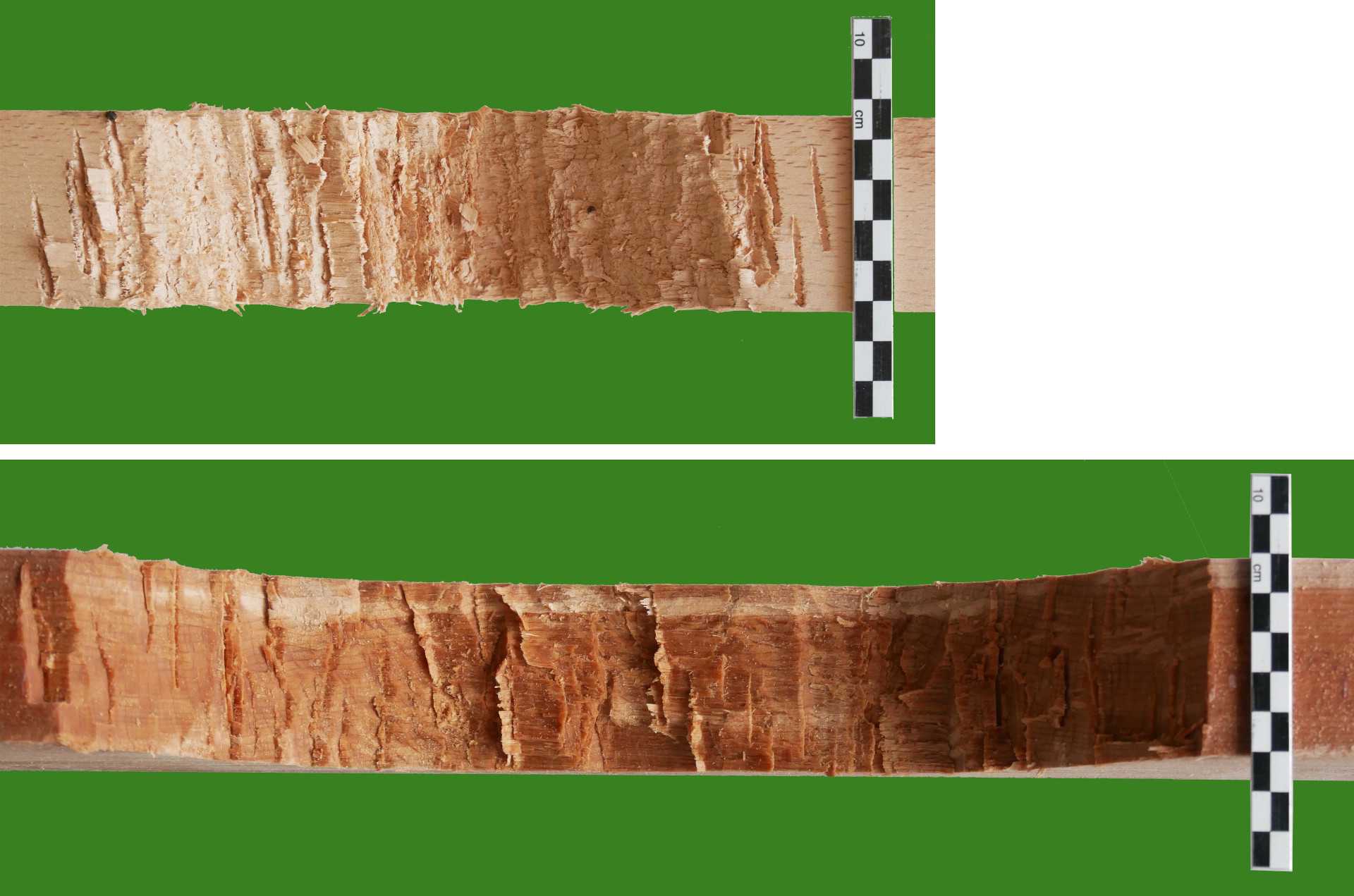

Documentation of full view

take image of full view, including a scale bar, angled to give an idea of the three-dimensional quality of the contact sample

Documentation of notch

take detail image of notch as vertical shot, including a scale bar

Comparative documentation

Optionally, further images may be taken to directly compare contact samples.

Determination of moisture content (oven-drying method)

Determination of moisture content (oven-drying method)

determine precise moisture content by oven-drying contact sample until weight constancy is reached, i.e. until weight discrepancy between two measurements at least two hours apart falls below 1‰

Equipment

| Value | Label |

|---|---|

| UT 6120 | NAME |

| air-circulation drying oven | TYPE |

| Heraeus | BRAND |

| - | SKU |

| - | LINK |

Loading drying oven

place contact samples in drying oven set to 103°C, recording starting date of oven-drying for each

Oven-drying

leave drying cabinet to run at 103°C on at least 3 to 5 (preferably consecutive) days (period may be shortened in repeat cycles)

Weighing contact samples

weigh contact samples (triple measurement); record result(s) along with the date and time for each

Equipment

| Value | Label |

|---|---|

| PCB 3500-2 | NAME |

| precision balance | TYPE |

| Kern | BRAND |

| - | SKU |

| - | LINK |

Waiting period / continued oven-drying

let (a minimum of) two hours elapse before next weight check

2h 0m 0s

Weighing contact samples and checking weight discrepancy

weigh contact samples (triple measurement); record result(s) along with the date and time for each; compare weight recorded in step 6.3

Equipment

| Value | Label |

|---|---|

| PCB 3500-2 | NAME |

| precision balance | TYPE |

| Kern | BRAND |

| - | SKU |

| - | LINK |

Waiting period / continued oven-drying

let (a minimum of) two hours elapse before next weight check

2h 0m 0s

Weighing contact samples and checking weight discrepancy

weigh contact samples (triple measurement); record result(s) along with the date and time for each; compare weight recorded in step 6.4

Equipment

| Value | Label |

|---|---|

| PCB 3500-2 | NAME |

| precision balance | TYPE |

| Kern | BRAND |

| - | SKU |

| - | LINK |

Calculation of moisture content

calculate and record the moisture content of the contact sample(s) using the formula

MC = (mwet - mdry)/mdry × 100%

in which mwet is the weight(/mass) recorded in step 4.3 and mdry is the lowest weight(/mass) recorded in steps 6.3, 6.5 and 6.7 (N.B.: not the lowest single measurement, but the lowest weight calculated as the mean of triple measurement)

Calculation of further attributes

Optionally, further attributes may be calculated at this point.

Storage

Storage

archive contact samples alongside samples