Measurement of biogenic silica from plankton

Ying-Yu Hu, Zoe V. Finkel, Nuwanthi Samarasinghe

Abstract

Here, we present a method for measuring biogenic silica from plankton. Biogenic silica is digested using a wet-alkaline method, in which 2 M sodium carbonate is used to hydrate and depolymerize amorphous silica, resulting in the production of monosilicic acid. The molybdate measurement technique is based on the method described by Shemesh et al. (1988) and follows the JGOFS protocols outlined by UNESCO (1994).

To ensure the accuracy of the measurement, Celite S diatomaceous earth is used as a check standard for the recovery of biogenic silica. Our method yields a recovery rate of 85% to 90%.

Steps

Sample collection

Estimation:

The low limit of detection is approximately 0.6 uM silicate in the molybdate method. For siliceous plankton, sample requires no less than 4 ug PON (particulate organic nitrogen) per filter when using a 50 mL volumetric flask, or 2 ug PON per filter when using a 25 mL volumetric flask. The sampling volume for biogenic silica samples is approximately 10% of the PON sample volume. For seawater samples, the sampling volume for biogenic silica samples should be determined based on the community composition.

Filter blank media (without cells, same volume as plankton samples) through polycarbonate filter as blank

Transfer filter into 2 mL cryogenic vial

Flash freeze and store at -20°C

Filter plankton sample in liquid media onto polycarbonate filters, using gentle vacuum pressure (130 mmHg)

Equipment

| Value | Label |

|---|---|

| Filter forceps | NAME |

| blunt end, stainless steel | TYPE |

| Millipore | BRAND |

| XX6200006P | SKU |

| http://www.emdmillipore.com/ | LINK |

Rinse filter funnel with filtered artificial seawater without macronutrients

Transfer filter with sample into 2 mL cryogenic vial

Flash freeze and store at -20°C

Transfer sample to 50 mL falcon tube with clean filter forceps (rinsed by 95% ethanol and air-dried), dry at 90°C in the airforce oven.

Equipment

| Value | Label |

|---|---|

| Forced air oven | NAME |

| VWR | BRAND |

| 89511-410 | SKU |

Equipment

| Value | Label |

|---|---|

| Falcon® Centrifuge Tubes | NAME |

| Polypropylene, Sterile, 50 mL | TYPE |

| Corning® | BRAND |

| 352070 | SKU |

Standard primary solution and reagents

Molybdate reagent stock solution

Ammonium paramolybdate:

[(NH4)6Mo7O24.4H2O]

CAS: 12054-85-2

Add 1.6g ammonium paramolybdate into a 125 mL plastic bottle and top to 100 g with MilliQ.

Store out of direct sunlight. Discard if white precipitation forms.

HCl stock solution

Use graduated cylinder, measure 95 mL MilliQ and transfer into a 125 mL plastic bottle.

In the fume hood, add 5mL 12 N HCl into the bottle, mix well.

Metol-sulfite solution

Require:

(1) 50 mL syringe

(2) Syringe filter

Equipment

| Value | Label |

|---|---|

| Syringe filter | NAME |

| 0.2 um PES | TYPE |

| VWR | BRAND |

| 28145-501 | SKU |

In a 100 to 250 mL plastic beaker, add 0.6g sodium sulphite.

Add 1g 4-(methyl amino)phenol hemisulfate.

Top to 50 g with MilliQ water.

Fill syringe with Metol-sulfite solution, filter through the syringe filter, collect filtrate into four 15 mL falcon tubes wrapped with foil, keep at room temperature.

Prepare fresh every month.

Oxalic acid solution

In a 125 mL plastic bottle, add 6g oxalic acid and top to 100 g.

Let the solution stand at room temperature overnight.

Decant the solution from the crystals into a plastic bottle.

Keep at room temperature.

Sulphuric acid (30%)

Mix 3 part concentrated sulphuric acid into 7 part of MilliQ

Cool down to room temperature

Primary silica standard solution (~ 1 mM Si)

Transfer 1 g sodium fluorosilicate in a plastic vial

Keep the vial in a vacuum desiccator overnight to remove excess water (do not heat or fuse)

In a one litre plastic volumetric flask, dissolve ~0.1881g (log the actual mass) of dry sodium fluorosilicate in MilliQ water and top to 1 L with MilliQ water.

It takes about 30 min to complete the dissolution. This cannot be rushed.

Store in a plastic bottle at room temperature.

Day 1: Dissolution

2M Na2CO3(18.69%)

Each sample requires 10 mL 2 M Na2CO3

Weigh 186.9 g Na2CO3in a weighing dish.

(CAS: 497-19-8, FW 105.99)

Tare a 1 L plastic erlenmeyer flask

Transfer Na2CO3into the flask

Top to 1000 g with MilliQ and shake until all salt is completely dissolved.

Aliquot the solution into four 250 mL plastic bottles.

Turn on airforce oven to 85°C

In the fume hood, transfer diatomaceous into a 5 mL plastic tube for weighing convenience (the original package is 1 kg).

Weigh 100~200 ug diatomaceous into 50 mL falcon tube, in triplicate. Log the actual weight.

Prepare one empty 50 mL falcon tube as the reagent blank for diatomaceous.

Add 10mL 2 M Na2CO3 to each tube, including:

- reagent blank for check standards

- check standards

- blank for samples

- samples

Vortex

Loose the caps and place all tubes into the airforce oven overnight (for example, from 5 pm to 9 am).

Day 2: Acidification

Volume of 12 N HCl required:

3.5 mL X N

Transfer 12 N HCl into a 50 mL Falcon tube in the fume hood.

Work on one tube at a time, and leave other tubes in the oven.

In the fume hood, add 30µL Methyl orange into the tube.

Add MilliQ until the volume of solution in the falcon tube is 10 mL.

Dropwise add 3mL 12 N HCl by using 1000 uL pipet.

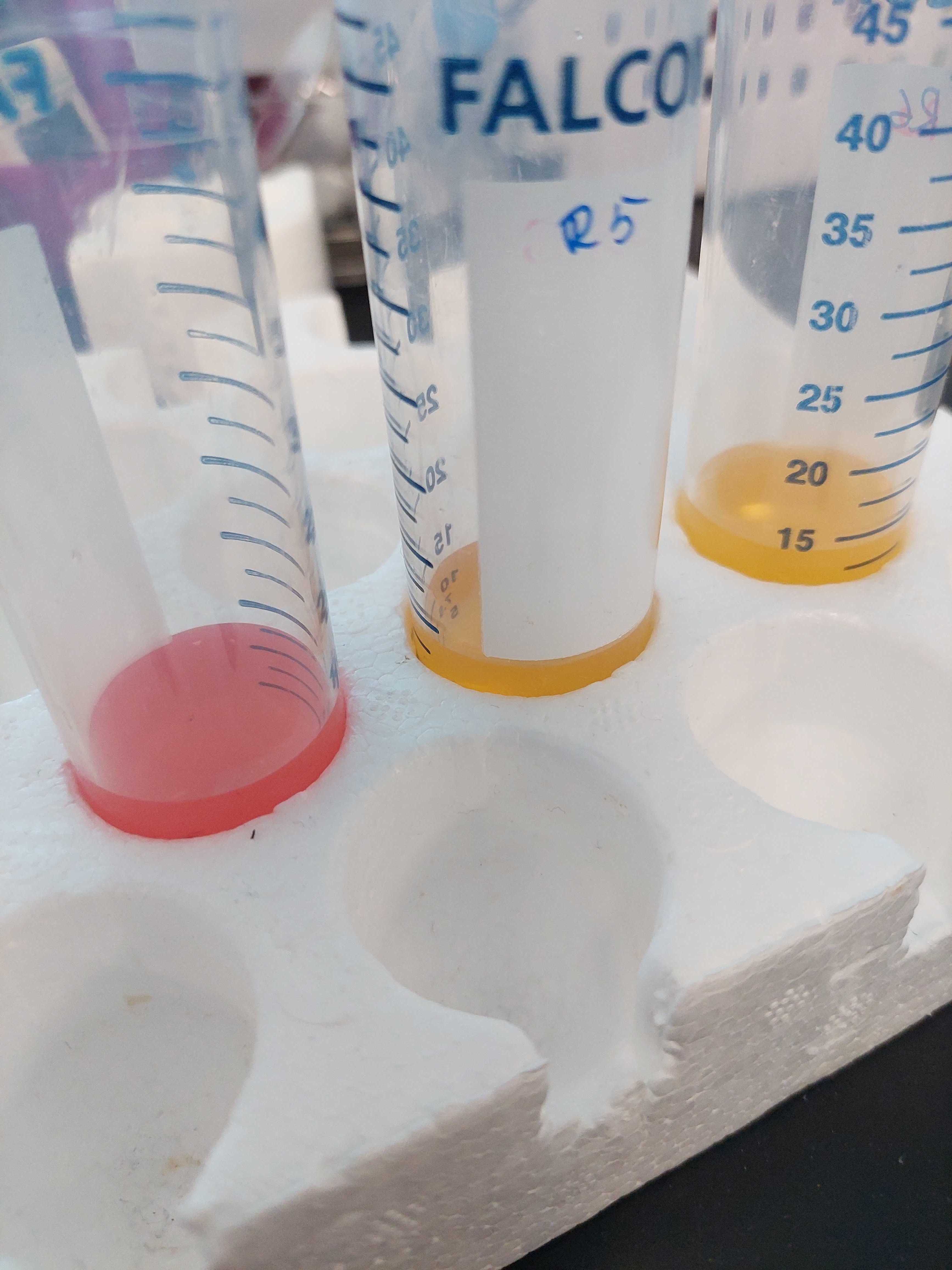

Switch to a 100 uL pipette, add 100 uL at a time. Near the equivalence point, when the colour starts to change to pink more markedly but after mixing the orange colour returns, it is necessary to add HCl drop by drop . The first drop that causes a permanent colour change to pink determines the equivalence point. Stop adding HCl. Cap the tube, hold tube horizontally, gently invert the tube to wash residue at the inner side of the cap down to the solution. The color may change back to orange, add more drops of HCl until the color turns to permanent pink again (See the color of the left tube).

Transfer resulted solution from falcon tube to 25 or 50 mL polypropylene volumetric flask.

Use MilliQ to rinse the tube three times and transfer all samples into the volumetric flask.

Use transfer pipet, top final volume to 25 or 50 mL with Milli-Q.

Shake and thoroughly mix the solution.

Transfer solution from volumetric flask to a clean and labelled Falcon tube.

Day 2: Molybdate reaction

Secondary standard solution (Freshly prepared prior to the assay)

50 uL primary stock solution

450 uL MilliQ

Standard working solutions (Freshly prepared prior to the assay)

| A | B | C | D |

|---|---|---|---|

| S1 | 0 | 500 | 0 |

| S2 | 5 | 495 | 1 |

| S3 | 10 | 490 | 2 |

| S4 | 20 | 480 | 4 |

| S5 | 40 | 460 | 8 |

| S6 | 60 | 440 | 12 |

| S7 | 80 | 420 | 16 |

| S8 | 100 | 400 | 20 |

Vortex and then transfer 50µL from (1) blank for check standards, (2) check standards, (3) blank for samples, and (4) samples into labelled 2 mL microtubes.

Add 450µL MilliQ into each tube to obtain a 10% dilution.

Molybdate working solution

1 part Molybdate stock reagent

1 part HCl stock reagent

Add 200µL Molybdate reagent into each tube.

Vortex each tube and then shake at Room temperature for 0h 15m 0s for the formation of silicomolybdic acid.

Reducing solution

1 part Metol-sulfite solution

1 part oxalic acid solution

1 part sulphuric acid solution

Add 300µL reducing solution into each tube.

Vortex each tube and then shake at Room temperature for 3h 0m 0s

Measure pH of each sample (in the Falcon tube)

| A | B | C |

|---|---|---|

| Blank for check standards | ||

| Check standard 1 | ||

| Check standard 2 | ||

| Check standard 3 | ||

| Blank for samples | ||

| Sample 1 | ||

| Sample 2 | ||

Day 2: Colorimetric measurement

In the fume hood, vortex each tube and then load 250 µL of the sample into one well of the microplate. Vortex again and load the same sample into another well of the microplate as replicate.

Equipment

| Value | Label |

|---|---|

| 96-Well Microplates, Polystyrene, Clear, | NAME |

| Greiner Bio-One | BRAND |

| 655101 | SKU |

Setup the layout.

Setup the program

| A | B |

|---|---|

| Shake duration | 00:00:05 |

| Shaking type | Continuous |

| Shaking force | High |

| Shaking speed [rpm] | 600 |

| Wavelength [nm] | 812 |

| Use transmittance | No |

| Pathlength correction | No |

| Measurement Time [ms] | 100 |

Equipment

| Value | Label |

|---|---|

| Varioskan LUX Multimode Microplate Reader | NAME |

| Thermo Fisher | BRAND |

| VL0L00D0 | SKU |

Read the samples.

Export data sheet to excel.

Waste disposal

Collect all solution with paramethylaminophenol sulphate and sodium fluorosilicate into the waste container.

Rinse microtubes and microplate with tap water, dispose in blue recycling bin.

Day 2: Calculation

Subtract the average absorbance at 812 nm of the blank standard replicates from the absorbance at 812 nm of all other standard working solutions.

Subtract the average absorbance at 812 nm of the blank sample (i.e. blank filter) replicates from the absorbance at 812 nm of all other individual samples.

Use the standard curve to determine the silicate concentration of each unknown sample by using its blank-corrected 812 nm absorbance.

Si per sample = Si X V X (0.001) X DF

| A | B | C |

|---|---|---|

| Si per sample | umol | element Si in the sample collected |

| Si | uM | silicate concentration calculated from the standard curve |

| V | mL | volume of volumetric flask |

| DF | From volumetric flask to the microtube, DF=10 |

% Diatomaceous recovery = 100 X Si X V X (0.001) X MW X DF /(M_ug X Purity X 0.01)

| A | B | C |

|---|---|---|

| % Diatomaceous recovery | percentage recovery of diatomaceous | |

| Si | uM | silicate concentration calculated from the standard curve |

| V | mL | volume of volumetric flask |

| MW | ug/umol | molecular mass of SiO2, i.e. 60.08 |

| DF | From volumetric flask to the microtube, DF=10 | |

| M | ug | actual mass of diatomaceous |

| Purity | purity of SiO2 in Celite S diatomaceous earth (06858) is 90.2% |