DAPI-Based Polyphosphate Estimation with Extraction Sufficiency Validation: A Method for Quantifying Polyphosphate from Microalgae Samples

Ying-Yu Hu, Zoe V. Finkel

Abstract

The utilization of DAPI-based fluorometric estimation for polyphosphate (polyP) analysis from microalgae has become increasingly prevalent in field samples since its publication by Martin P. et al. This technique involves evaluating the fluorescence of DAPI-stained samples in quartz cuvettes using a spectrofluorometer. To reduce the consumption of reagent, time, and labor while minimizing DAPI photobleaching, we have adapted this method to a 96-well black microtiter plate with a black film-covered lid. Additionally, the calculation method has been modified to account for matrix effects in microplates.

Testing the number of treatment rounds necessary to extract all polyP is crucial. However, even when collecting samples from the same field location or cultivation condition, there can be high variability in treatment rounds among replicates, leading to significant background fluorescence and rendering the polyP from the sample undetectable. This challenge is especially prominent when measuring polyP from field samples. Limited sample availability and insufficient polyP extraction, combined with high background fluorescence, make the laborious measurement unpredictable and hinder accurate polyP measurement. This obstacle is a significant hurdle in polyP measurement.

In our assay, we overcome the challenge by validating the sufficiency of extraction for each sample and then measuring the polyP values.

To conduct the assay, roughly 400 uL RNase, 400 uL DNase, and 700 uL proteinase are required for four samples.

Before start

Steps

Sample collection

Filter microalgae in liquid media onto GFF or PC filters, using gentle vacuum pressure (5 inches Hg).

Equipment

| Value | Label |

|---|---|

| Filter forceps | NAME |

| blunt end, stainless steel | TYPE |

| Millipore | BRAND |

| XX6200006P | SKU |

| http://www.emdmillipore.com/ | LINK |

Rinse sample with filtered artificial seawater (no nutrients)

Place sample filters in cryogenic vials

Filter blank media (without cells) through GFF or PC filter as blank.

Flash freeze filters and stored at -20°C

Freeze dry before measurement.

Equipment

| Value | Label |

|---|---|

| FreeZone® 2.5 L Benchtop Freeze Dryers | NAME |

| Labconco® | BRAND |

| 700202000 | SKU |

Preparation of reagents

Tris buffer 20 7.0

In a 1 L volumetric flask, top 20mL 1 7.0 Tris buffer to 1 L with MilliQ

Store at Room temperature

PolyP primary standard stock

Weigh one glass pellet of polyP (45) and write down the weight.

Equipment

| Value | Label |

|---|---|

| Microbalance | NAME |

| Cubis series | TYPE |

| Sartorius | BRAND |

| MSE6.6S-000-DM | SKU |

| https://www.fishersci.com/us/en/home.html | LINK |

Transfer the pellet into a 100 mL graduated cylinder.

Dilute to 100 mL with Tris 20 7.0

Aliquot primary stock into 10~50 uL per microtube with Stepper and store at -20°C

PolyP secondary standard stock

If the pellet is far more than 10 mg, dilute primary to secondary to bring down the concentration before preparing working standard

Proteinase K 20

Add 25mL MilliQ directly into the original package of Proteinase K, vortex to mix

Aliquot 700 uL to microtubes and keep frozen at -20°C

DAPI primary stock 14.3

Add 2mL MilliQ directly into the original package and keep frozen at -20°C

Preliminary extraction efficiency test

Prepare boiling bath.

Equipment

| Value | Label |

|---|---|

| VWR® Advanced Hot Plates | NAME |

| VWR | BRAND |

| 97042-658 | SKU |

Equipment

| Value | Label |

|---|---|

| Hollow Polypropylene (PP) Ball Bath Covers, 20 mm | NAME |

| Cole-Parmer | BRAND |

| UZ-06821-04 | SKU |

| http://www.coleparmer.com | LINK |

Equipment

| Value | Label |

|---|---|

| Tube rack | NAME |

| Simport MultiRack™ | BRAND |

| CA48648-606 | SKU |

Prepare 37°C incubator/shaker.

Transfer sample into glass centrifuge tube

Equipment

| Value | Label |

|---|---|

| Disposable Glass Screw-Cap Centrifuge Tubes | NAME |

| 10 mL | TYPE |

| Corning® | BRAND |

| 99502-10 | SKU |

Label centrifuge tube for different samples, place one Pasteur pipet into the tube for transferring extract from the same sample

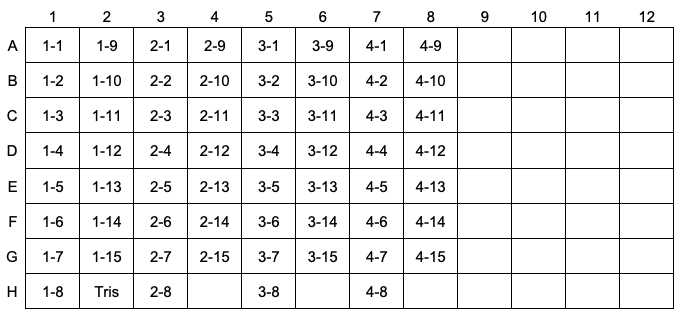

Label 15 mL Falcon tube from 1 to 15 for each one sample.

Add 4mL Tris buffer 20 7.0 , vortex and then sonicate.

Equipment

| Value | Label |

|---|---|

| Specific Pipette Tips 5mL | NAME |

| Thermo Scientific™ Finntip™ | BRAND |

| 21-377-304 | SKU |

| https://www.lifetechnologies.com | LINK |

Keep in boiling bath.

Sonicate

Vortex and then transfer extract to 15 mL Falcon tube, according to the extract number.

Equipment

| Value | Label |

|---|---|

| Disposable Soda-Lime Glass Pasteur Pipets | NAME |

| 5 3/4" | TYPE |

| Fisherbrand | BRAND |

| 13-678-6A | SKU |

| https://www.fishersci.com/us/en/home.html | LINK |

Repeat Step 17 to Step 20 until complete 15 times' extraction in total.

Centrifuge the extract

3200rpm

Prepare DAPI working solution 100

Dilute 12.6µL of 14.3 DAPI stock with 1800µL MilliQ in a foil wrapped microtube and vortex.

In the dimmed room with only red light bulb on add 24µL 100 DAPI to each sample in the plate.

Adhere black film on the top of a microplate lid and cover the plate with this lid.

Equipment

| Value | Label |

|---|---|

| Black Vinyl Films for Fluorescence and Photoprotection | NAME |

| VWR | BRAND |

| 89087-692 | SKU |

Shake at room temperature for 0h 7m 0s

Read fluorescence: excitation at 410 nm and emission at 550 nm

Equipment

| Value | Label |

|---|---|

| Varioskan LUX Multimode Microplate Reader | NAME |

| Thermo Fisher | BRAND |

| VL0L00D0 | SKU |

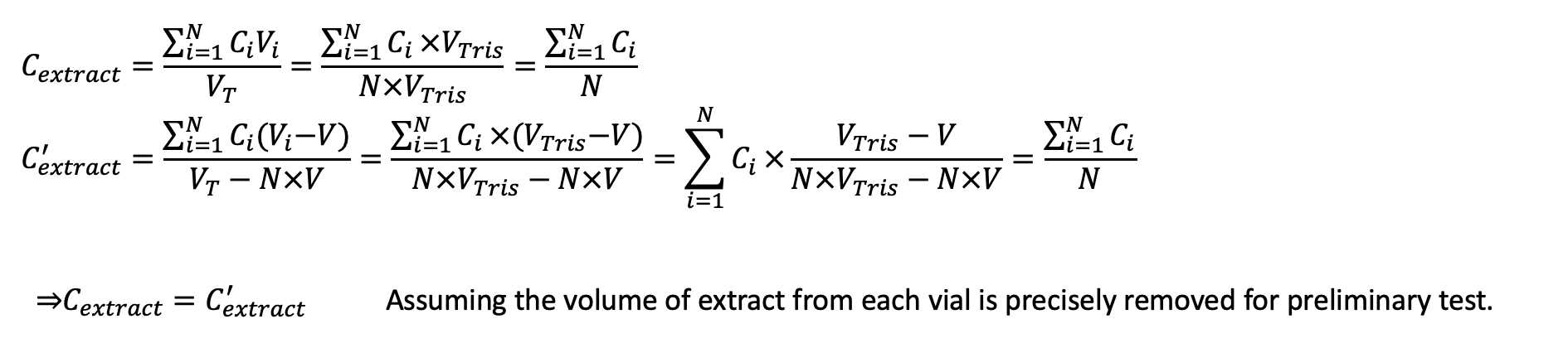

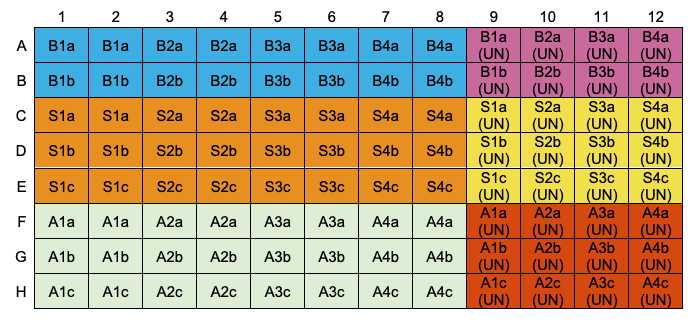

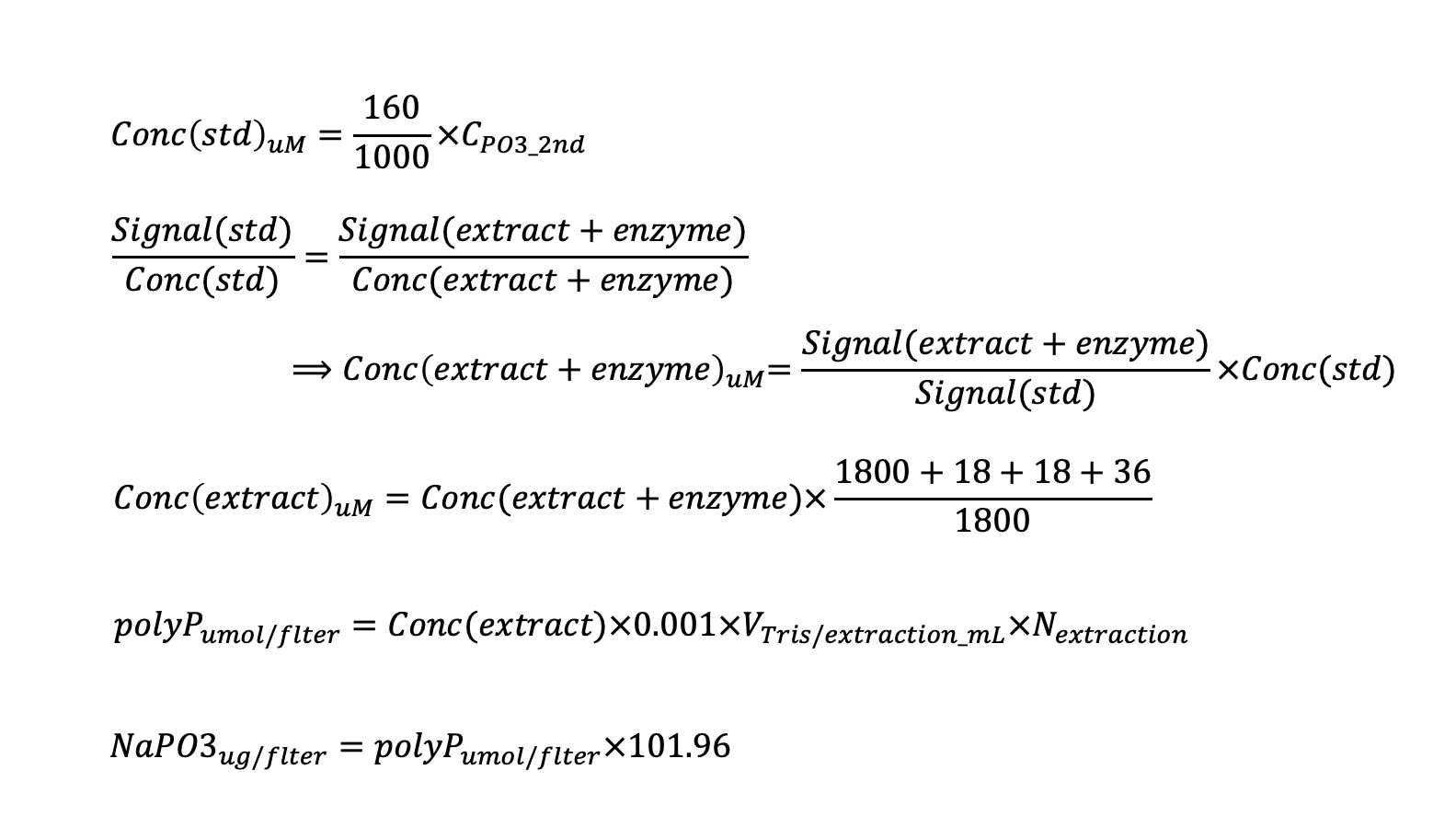

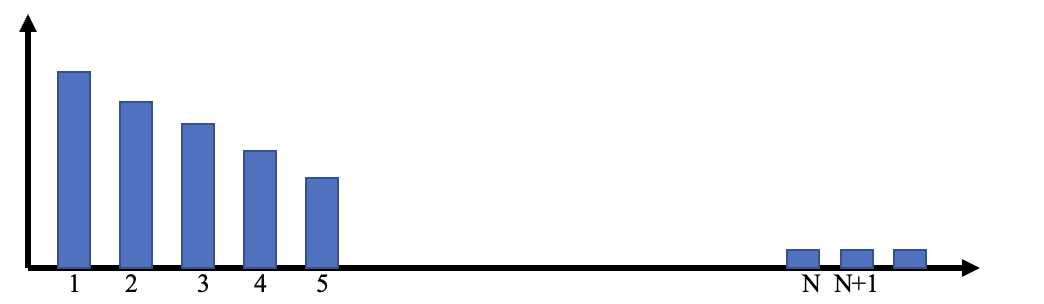

Plot fluorescence intensity versus number of extraction.

The number of extract (N) is the stationary point where the fluorescence of stained extract stops decreasing or the derivative of the fluorescence after that point is close to zero.

If

Combine Extraction 1 to Extraction N into a falcon tube.

| A | B | C |

|---|---|---|

Enzyme treated extract

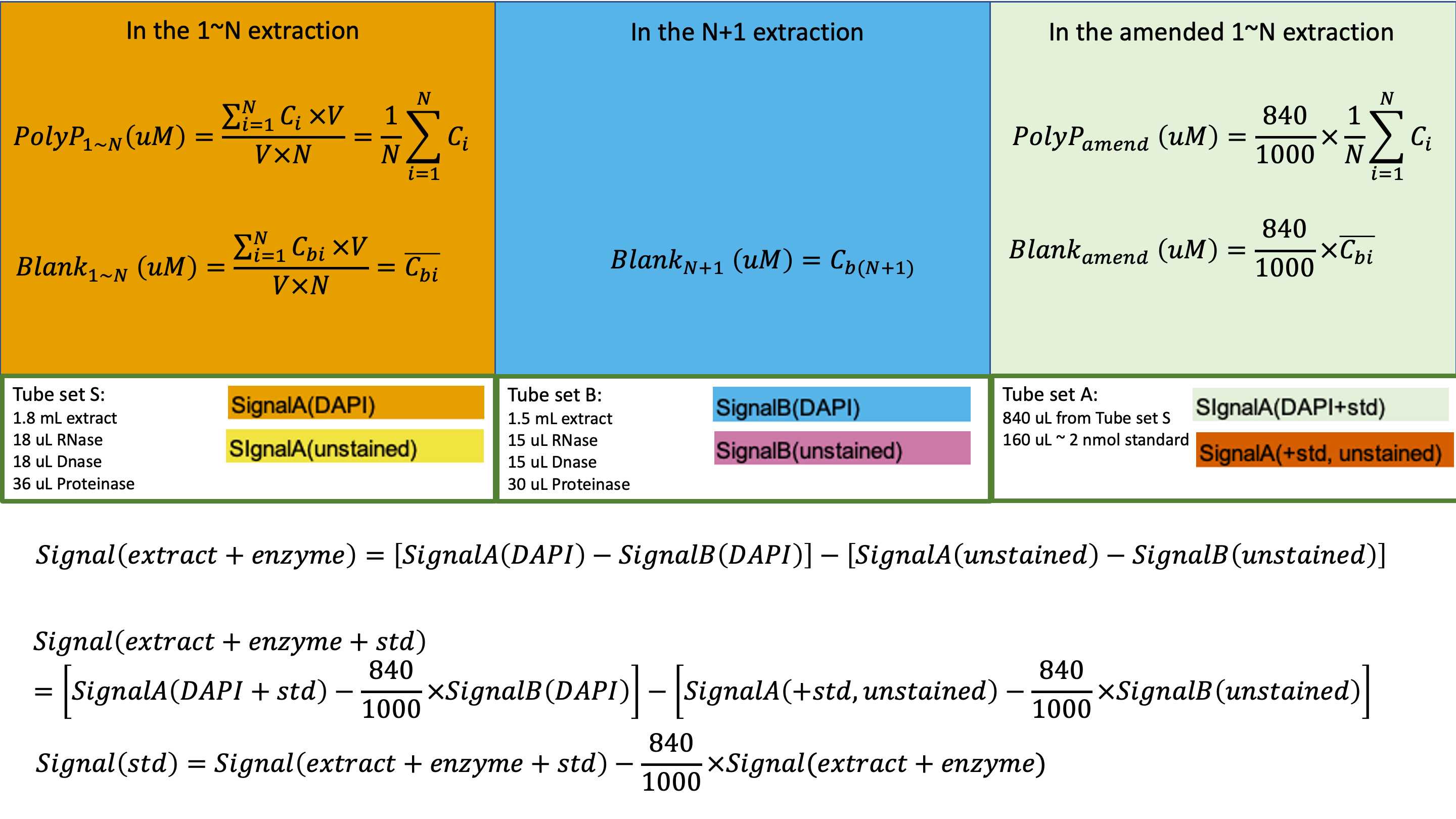

Well mix 1~N extract, transfer 12 mL into 15 mL falcon tube, centrifuge 3200rpm

Transfer 1.8mL supernatant to a 2 mL tube (Set S).

Centrifuge extract "N+1" 3200rpm

Transfer 1.5mL supernatant into a 2 mL tube (Set B).

In Set S, add 18µL RNase and 18µL DNase

In Set B, add 15µL RNase and 15µL DNase

Incubate at 37°C, shake continuously

Equipment

| Value | Label |

|---|---|

| SHAKING INCUBATOR | NAME |

| 71L | TYPE |

| Corning® LSE™ | BRAND |

| 6753 | SKU |

Thaw proteinase (~700uL)

In Set S, add 36µL Proteinase

In Set B, add 30µL Proteinase

Incubate at 37°C, shake continuously.

Enzyme treated standard amended extract

Prepare PolyP working standard [PO3]~7.6

Based on the actual concentration of PolyP (45) primary or secondary standard stock, dilute a certain volume of stock with Tris buffer 20 7.0

For a final concentration 7.6

Transfer 840µL of enzyme treated extract (1~N) into 2 mL tubes (Set A).

Add 160µL 7.6 polyP working standard to 840µL of enzyme treated extract, vortex.

Prepare DAPI working solution 100

Dilute 12.6µL of 14.3 DAPI stock with 1800µL MilliQ in a foil wrapped microtube and vortex.

Load microtiter plate

In a dimmed room with only red bulb on, add 24µL DAPI working solution 100 to each sample in the microplate except for those labelled with (UN) .

Adhere black film on the top of a microplate lid and cover the plate with this lid.

Shake at room temperature for 0h 7m 0s

Shake duration: 1 min

Shaking type: continuous

Shaking speed and force: 600 rpm/High

Fluorescence: excitation at 410 nm and emission at 550 nm

Measurement time: 300 ms

Excitation bandwidth: 5 nm